Cantieri Navali Caorle is equipped with workshops for all kinds of mechanical work and structural steel work and in alloy and synthetic and it extends its range of services to the field of assistance and plant engineering for accessories and equipment.

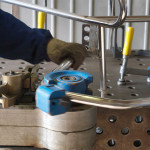

We have sophisticated equipment, with a lathe, press, polishers, various welders and benders, etc.

We have always attributed primary importance to the transmission, to the type of navigation and to the result that is achieved. Consisting of axle lines and relative seals, stands, rudders, transmissions and articulations, etc… but above all propellers. All of these components are important, which is why we use equipment that allows us workings such as axles, fringes and couplings done on the lathe and everything needed for scrupulous maintenance and repair.

However, it is the propellers that we look at with particular attention, which is why we have built an important laboratory for straightening and balancing, with prime equipment and a computerised balancing machine for propellers with a diameter of up to 1,80 metres with a certificate that is issued on completion.

Our workers’ skill and experience have given us a reputation for quality and precision work, as well as inventiveness and creativity gained as a result of over thirty years in business.

All of this has enabled craftsmanlike work to be achieved such as:

– pulpits, structures for covers and Bimini tops in stainless steel tube

– equipment and accessory creations and reproductions in metal in general

– bushes, washers and components in nylon, Teflon and compounds

– hydraulic plant engineering in general

– water plant engineering

– tanks in folded plate and also welded on form

– straightening, balancing and equilibrating propellers

– construction and correction axles